![]() The difference in degradation

behavior of titania-doped tin dioxide films is explained by a pronounced effect

of the doping level on the film dispersity and fine distribution of titania.

Two – three times decrease of nanoparticles size in doped films compared to

nanoparticles in SnO2 film (20 – 30 nm) is revealed by using

scanning tunneling microscopy (STM). STM data (measured in ex situ configuration) combined with XRD and Mössbauer

spectroscopy analysis confirm that nanoparticles are composed of nanostructured

heavily disordered SnO2 and TiO2 rutile solid solution or of amorphous phase

containing both SnO2 and TiO2, the content of

the crystalline and amorphous phases being approximately equal.

The difference in degradation

behavior of titania-doped tin dioxide films is explained by a pronounced effect

of the doping level on the film dispersity and fine distribution of titania.

Two – three times decrease of nanoparticles size in doped films compared to

nanoparticles in SnO2 film (20 – 30 nm) is revealed by using

scanning tunneling microscopy (STM). STM data (measured in ex situ configuration) combined with XRD and Mössbauer

spectroscopy analysis confirm that nanoparticles are composed of nanostructured

heavily disordered SnO2 and TiO2 rutile solid solution or of amorphous phase

containing both SnO2 and TiO2, the content of

the crystalline and amorphous phases being approximately equal.

![]() Keywords: Tin dioxide, lithium intercalation,

scanning tunneling microscopy and spectroscopy, nanostructure

Keywords: Tin dioxide, lithium intercalation,

scanning tunneling microscopy and spectroscopy, nanostructure

![]() Nanostructured SnO2-based

compositions well-known as materials for gas sensors [1, 2] were recently found

to be also prospective candidates for lithium batteries [3-5]. The initial cathodic

polarization of doped tin oxides in solutions of lithium salts results in the

irreversible reduction of oxide with formation of metallic tin. Thus formed

metallic tin dispersed in oxide matrix demonstrates the reversible

absorption-desorption of lithium with formation of intermetallic compound Li4.4Sn.

Correspondingly, irreversible (observed in the course of initial charging) and

reversible contributions to capacity can be separated. The size of initial

oxide particles is responsible for the values of capacity components and

stability of lithium recharging (see, for example, in Ref. [4]). A serious

problem results from the gradual increase of the size of metal particles,

which, in turn, induces the decrease of reversible capacity in respect to

lithium.

Nanostructured SnO2-based

compositions well-known as materials for gas sensors [1, 2] were recently found

to be also prospective candidates for lithium batteries [3-5]. The initial cathodic

polarization of doped tin oxides in solutions of lithium salts results in the

irreversible reduction of oxide with formation of metallic tin. Thus formed

metallic tin dispersed in oxide matrix demonstrates the reversible

absorption-desorption of lithium with formation of intermetallic compound Li4.4Sn.

Correspondingly, irreversible (observed in the course of initial charging) and

reversible contributions to capacity can be separated. The size of initial

oxide particles is responsible for the values of capacity components and

stability of lithium recharging (see, for example, in Ref. [4]). A serious

problem results from the gradual increase of the size of metal particles,

which, in turn, induces the decrease of reversible capacity in respect to

lithium.

![]() An alternative

concept of lithium intercalation by tin oxides stresses the role of Sn-O-Li

nanoscalephases, not intermetallic compounds. The stability of nanoscale phases

in relation to reduction by lithium determines more slow growth of tin

crystallities [6]. When some foreign oxides (like B2O3,

Al2O3 or P2O5) are inserted to form

dispersed amorphous tin-based composite oxide, the best long-term cycling is

achieved resulting from high stability in respect to reduction [7].

An alternative

concept of lithium intercalation by tin oxides stresses the role of Sn-O-Li

nanoscalephases, not intermetallic compounds. The stability of nanoscale phases

in relation to reduction by lithium determines more slow growth of tin

crystallities [6]. When some foreign oxides (like B2O3,

Al2O3 or P2O5) are inserted to form

dispersed amorphous tin-based composite oxide, the best long-term cycling is

achieved resulting from high stability in respect to reduction [7].

![]() Nanoheterogeneous titania-doped tin

oxide films prepared by thermohydrolytic decomposition of SnCl2 and

TiCl4 solutions can be considered as prospective charge-accumulating

materials because of high conductivity, nanometer-scale size of constituents,

and mechanical stability in the course of prolonged cycling in aqueous

solutions [1, 2]. For lithium accumulation by the films of this type [8, 9],

the reversible capacity up to 650 mA h g-1 is found, with

satisfactory cycling stability.

Nanoheterogeneous titania-doped tin

oxide films prepared by thermohydrolytic decomposition of SnCl2 and

TiCl4 solutions can be considered as prospective charge-accumulating

materials because of high conductivity, nanometer-scale size of constituents,

and mechanical stability in the course of prolonged cycling in aqueous

solutions [1, 2]. For lithium accumulation by the films of this type [8, 9],

the reversible capacity up to 650 mA h g-1 is found, with

satisfactory cycling stability.

![]() Structural studies of multicomponent oxide film

electrodes (electrocatalysts, etc) prepared by the above mentioned technique

show that the reaction of hydrated species in solution followed by heat

treatment results in the formation of unusual nonequilibrium phases –

nanoheterogeneous solid solutions [10,11]. They have been found to be a mixture

of various oxide nanoclusters (RuO2, TiO2, IrO2,

SnO2) of less than 1-2 nm size, which are statistically distributed

in amorphous matrix formed by their hydrated precursors.

Structural studies of multicomponent oxide film

electrodes (electrocatalysts, etc) prepared by the above mentioned technique

show that the reaction of hydrated species in solution followed by heat

treatment results in the formation of unusual nonequilibrium phases –

nanoheterogeneous solid solutions [10,11]. They have been found to be a mixture

of various oxide nanoclusters (RuO2, TiO2, IrO2,

SnO2) of less than 1-2 nm size, which are statistically distributed

in amorphous matrix formed by their hydrated precursors.

![]() According to STM, XRD and XPS

studies, SnO2 films containing 10 mol % TiO2 (ST10),

annealed at 450°C

consist of globules of 15 – 20 nm size, which in turn have a fine nanostructure

[1, 2, 11]. The cores

of globules contain crystallites of (Sn, Ti)O2 rutile solid

solution (6–8 nm) pierced with amorphous SnO2 strips. The similar

amorphous SnO2 layers containing up to 15% SnO cover the globule

surface. Such nanostructure in ST10 films is due to the formation of the

crystalline SnCl2 intercalation phase as their precursor, which contains

inclusions of polynuclear titanium-tin oxohydroxo complexes.

According to STM, XRD and XPS

studies, SnO2 films containing 10 mol % TiO2 (ST10),

annealed at 450°C

consist of globules of 15 – 20 nm size, which in turn have a fine nanostructure

[1, 2, 11]. The cores

of globules contain crystallites of (Sn, Ti)O2 rutile solid

solution (6–8 nm) pierced with amorphous SnO2 strips. The similar

amorphous SnO2 layers containing up to 15% SnO cover the globule

surface. Such nanostructure in ST10 films is due to the formation of the

crystalline SnCl2 intercalation phase as their precursor, which contains

inclusions of polynuclear titanium-tin oxohydroxo complexes.

![]() Some two-three times larger titania-free

SnO2 globules were observed [11]. Hydrous tin oxide, which was

formed in the course of condensation of polynuclear species {SnOx(OH)6-x}n

has been found [11] to be the precursor of that phase. The latter species result

from hydrolysis of [Sn (IV)Cl4]L2 (L = OH, H2O)

complexes presenting in initial SnCl2 solution due to the partial

oxidation Sn(II) - > Sn(IV).

Some two-three times larger titania-free

SnO2 globules were observed [11]. Hydrous tin oxide, which was

formed in the course of condensation of polynuclear species {SnOx(OH)6-x}n

has been found [11] to be the precursor of that phase. The latter species result

from hydrolysis of [Sn (IV)Cl4]L2 (L = OH, H2O)

complexes presenting in initial SnCl2 solution due to the partial

oxidation Sn(II) - > Sn(IV).

![]() The role of TiO2 in creating

high charge storing properties of SnO2 remains unclear.

The role of TiO2 in creating

high charge storing properties of SnO2 remains unclear.

![]() The aim of this work was to obtain single

phase SnO2-based materials with a variable TiO2 content

and to study their structure, morphology, and electrochemical properties. At this stage the study is limited

to freshly prepared films, providing the basis for further understanding of

micro- and nanostructural changes induced by lithiation/delithiation. In this

study, we report as observed by using of STM, X-ray diffraction, and Mössbauer

spectroscopy.

The aim of this work was to obtain single

phase SnO2-based materials with a variable TiO2 content

and to study their structure, morphology, and electrochemical properties. At this stage the study is limited

to freshly prepared films, providing the basis for further understanding of

micro- and nanostructural changes induced by lithiation/delithiation. In this

study, we report as observed by using of STM, X-ray diffraction, and Mössbauer

spectroscopy.

![]() The condition of the synthesis of a new series

of SnO2 – TiO2 films (further designated as STx, where x = 0, 10, and 20 mol % TiO2 (Fabrication mode differed

from previously used in [1,2,8], so the sample denoted ST10 and ST20 are not

identical to the samples described in these Refs.)).

While the concentration of SnCl2 solution remained the same as in

[1,2,8] (0.067 M), the concentration of TiCl4 was increased by the

order of magnitude and amounted 1 M. It is known that in aqueous hydrochloric

acid solution of TiCl4 (cTi

= 0.01 – 0.05 mol/l and cHCl

= 0.1-2.0 mol/l) mono- and polynuclear forms of Ti (IV) hydroxyoxo complexes

exist for the latter [(TiO)8(OH)12]4+ species

predominate [12]. The rising of TiCl4 concentration (0.35 – 1.2

mol/l) (cHCl = 1

mol/l) resulted in the increase of the number of polynuclear complexes and the

degree of their polymerization. These polymeric species appear in essence the

nuclea of the hydrated titanium oxide [13]. The solutions were applied layer by

layer onto titanium supports pretreated by mechanical polishing and etching in

sulfuric acid. The temperature of annealing was 450oC for doped

films, 350oC and 450oC for pure tin oxide.

The condition of the synthesis of a new series

of SnO2 – TiO2 films (further designated as STx, where x = 0, 10, and 20 mol % TiO2 (Fabrication mode differed

from previously used in [1,2,8], so the sample denoted ST10 and ST20 are not

identical to the samples described in these Refs.)).

While the concentration of SnCl2 solution remained the same as in

[1,2,8] (0.067 M), the concentration of TiCl4 was increased by the

order of magnitude and amounted 1 M. It is known that in aqueous hydrochloric

acid solution of TiCl4 (cTi

= 0.01 – 0.05 mol/l and cHCl

= 0.1-2.0 mol/l) mono- and polynuclear forms of Ti (IV) hydroxyoxo complexes

exist for the latter [(TiO)8(OH)12]4+ species

predominate [12]. The rising of TiCl4 concentration (0.35 – 1.2

mol/l) (cHCl = 1

mol/l) resulted in the increase of the number of polynuclear complexes and the

degree of their polymerization. These polymeric species appear in essence the

nuclea of the hydrated titanium oxide [13]. The solutions were applied layer by

layer onto titanium supports pretreated by mechanical polishing and etching in

sulfuric acid. The temperature of annealing was 450oC for doped

films, 350oC and 450oC for pure tin oxide.

![]() X-ray dispersion analysis confirmed that the

content of SnO2 and TiO2 in films matched to the nominal

composition of Sn and Ti cations in original solution. Besides about 1% of

chlorine was found. XPES analysis showed that about 25 % of oxygen atoms

present in hydroxogroups, and 5% in aqua groups.

X-ray dispersion analysis confirmed that the

content of SnO2 and TiO2 in films matched to the nominal

composition of Sn and Ti cations in original solution. Besides about 1% of

chlorine was found. XPES analysis showed that about 25 % of oxygen atoms

present in hydroxogroups, and 5% in aqua groups.

![]() For electrochemical measurements, 1

M LiN(CF3SO2)2 in dioxolane was used as electrolyte

(water content below 70 ppm). Compartments of the three-electrode cell were

separated with porous membranes (polypropylene PORP). Potentials were measured

and are referred below vs. lithium reference electrode. Before starting the

experiments, oxide films were additionally dried under vacuum at 120oC

for 8 hours. EL-2 potentiostat designed in the Frumkin Institute, RAS, was

used.

For electrochemical measurements, 1

M LiN(CF3SO2)2 in dioxolane was used as electrolyte

(water content below 70 ppm). Compartments of the three-electrode cell were

separated with porous membranes (polypropylene PORP). Potentials were measured

and are referred below vs. lithium reference electrode. Before starting the

experiments, oxide films were additionally dried under vacuum at 120oC

for 8 hours. EL-2 potentiostat designed in the Frumkin Institute, RAS, was

used.

![]() For XRD, DRON-3M diffractometer run

by PC was used. For the decomposition of intensity profiles to multicomponent spectra

PROFITVZ program [14] was used. We could not perform quantitative analysis for

the electrodes studied since the lines of titanium support superimposed

practically all intensive rutile lines (besides 110) and prevented correct decomposition

of mixed maximums. The instrumental broadening b was too small (0.21 degree 2q) to make the corrections in FWHM (Full Width

at Half Maximum) value, therefore the latter was considered as b (diffraction broadening).

For XRD, DRON-3M diffractometer run

by PC was used. For the decomposition of intensity profiles to multicomponent spectra

PROFITVZ program [14] was used. We could not perform quantitative analysis for

the electrodes studied since the lines of titanium support superimposed

practically all intensive rutile lines (besides 110) and prevented correct decomposition

of mixed maximums. The instrumental broadening b was too small (0.21 degree 2q) to make the corrections in FWHM (Full Width

at Half Maximum) value, therefore the latter was considered as b (diffraction broadening).

![]() The samples

were studied with a conventional Mössbauer spectrometer. The

velocity drive of this spectrometer operates under the constant acceleration

mode over 1024 channels. The velocity scale of the Mössbauer spectra was

calibrated with a reference spectrum of metallic iron. All measurements were

carried out at room temperature. The Conversion Electron Mössbauer

Spectroscopy (CEMS) measurements were carried out using a gas detector with He + 5%CH4

as the flow-gas. In the (CEMS) method internal conversion electrons and Auger

electrons associated with the de-excitation of Mössbauer nuclei are

detected in the sample under study. Due to the small range of electrons in

solids this method is especially convenient for studying subsurface regions of

the order of a few hundreds atomic layers. 5 mCi CaSn119mO3

was used as g-ray

source in this experiment.

The samples

were studied with a conventional Mössbauer spectrometer. The

velocity drive of this spectrometer operates under the constant acceleration

mode over 1024 channels. The velocity scale of the Mössbauer spectra was

calibrated with a reference spectrum of metallic iron. All measurements were

carried out at room temperature. The Conversion Electron Mössbauer

Spectroscopy (CEMS) measurements were carried out using a gas detector with He + 5%CH4

as the flow-gas. In the (CEMS) method internal conversion electrons and Auger

electrons associated with the de-excitation of Mössbauer nuclei are

detected in the sample under study. Due to the small range of electrons in

solids this method is especially convenient for studying subsurface regions of

the order of a few hundreds atomic layers. 5 mCi CaSn119mO3

was used as g-ray

source in this experiment.

![]() For tunneling

microscopy experiments, homemade LitScan-2 device with extended spectroscopic

facilities was used. Pt-Ir tips (10% Ir) of 0.5 mm diameter were mechanically

sharpened. In topographic experiments, bias was 1.3 V (positively polarized

tip), and STM current was 0.3 nA. The technique of measuring the local spectra

is discussed in detail in [15]. Voltage-current spectra were measured under a

pulse mode, in order to avoid the shift of tip location in the course of

measurements. Voltage-distance spectra were registered under open feedback

loop, with the scan rates not exceeding 0.5 V s-1. Numerous

(100-150) repeated measurements of current-voltage and voltage-distance spectra

were carried out for all samples. These data were collected for various points

inside the area within the limits of piezomanipulator movement, and also for

various surface regions and experimental sets. Good reproducibility of the key

characteristic features of the tunneling spectra was found for each certain

type of oxide. Most typical spectra without any averaging or pretreatment are

presented in this article.

For tunneling

microscopy experiments, homemade LitScan-2 device with extended spectroscopic

facilities was used. Pt-Ir tips (10% Ir) of 0.5 mm diameter were mechanically

sharpened. In topographic experiments, bias was 1.3 V (positively polarized

tip), and STM current was 0.3 nA. The technique of measuring the local spectra

is discussed in detail in [15]. Voltage-current spectra were measured under a

pulse mode, in order to avoid the shift of tip location in the course of

measurements. Voltage-distance spectra were registered under open feedback

loop, with the scan rates not exceeding 0.5 V s-1. Numerous

(100-150) repeated measurements of current-voltage and voltage-distance spectra

were carried out for all samples. These data were collected for various points

inside the area within the limits of piezomanipulator movement, and also for

various surface regions and experimental sets. Good reproducibility of the key

characteristic features of the tunneling spectra was found for each certain

type of oxide. Most typical spectra without any averaging or pretreatment are

presented in this article.

![]() X-ray analysis revealed that the ST10 and ST20

films contained a single crystalline phase. The decomposition of the profile of

each reflection by program PROFITVZ evidenced that only one rutile phase gave

the contribution to the intensity profile. Maximums in the mixed films patterns

are very weak and diffuse (Fig.1).

X-ray analysis revealed that the ST10 and ST20

films contained a single crystalline phase. The decomposition of the profile of

each reflection by program PROFITVZ evidenced that only one rutile phase gave

the contribution to the intensity profile. Maximums in the mixed films patterns

are very weak and diffuse (Fig.1).

|

| Fig.1. The results of the decomposition of (110) reflection to possible multicomponents. a, b and c present the decomposition of (110) reflection for SnO2, ST10 and ST20 electrodes, respectively, and show doublet (a1 and a2 ) for only one rutile phase. |

![]() That effect may point to the dispersion of

crystallites or/and to the microdistortions (disordered crystal structure), as

well as to the presence of amorphous phase. The crystallinity of SnO2 electrode

is much higher. The increase of reflection FWHM with the 2q (Bragg angle)

proportional to tg q [16] testifies to the existing of microdistortion in

ST10 and ST20 electrodes. This may be connected with disordered structure of mixed

phase containing SnO2 and TiO2. This fact does not allow

to do the correct estimation of crystal size from XRD data. The FWHM of SnO2

film (amounted 0.854) practically does not change with 2q that points to

the effect of crystallites dispersion as the main contribution in the width of

lines. In the latter case the average size of crystallites about 11 nm was

calculated by means of Sherrer formula [16].

That effect may point to the dispersion of

crystallites or/and to the microdistortions (disordered crystal structure), as

well as to the presence of amorphous phase. The crystallinity of SnO2 electrode

is much higher. The increase of reflection FWHM with the 2q (Bragg angle)

proportional to tg q [16] testifies to the existing of microdistortion in

ST10 and ST20 electrodes. This may be connected with disordered structure of mixed

phase containing SnO2 and TiO2. This fact does not allow

to do the correct estimation of crystal size from XRD data. The FWHM of SnO2

film (amounted 0.854) practically does not change with 2q that points to

the effect of crystallites dispersion as the main contribution in the width of

lines. In the latter case the average size of crystallites about 11 nm was

calculated by means of Sherrer formula [16].

![]() The integral intensities of (110) reflections were

148, 80 and 80 relative units for the films with x = 0, 10 and 20, respectively. However, the heating of plain SnO2

film up to 450 oC resulted in the increase of line intensity of main

strong lines (~ 20% for (110), and 40% for (101) and (301), that is the degree

of crystallinity increased. All these data permit us to estimate that the

content of amorphous phase in mixed films is higher than 50%.

The integral intensities of (110) reflections were

148, 80 and 80 relative units for the films with x = 0, 10 and 20, respectively. However, the heating of plain SnO2

film up to 450 oC resulted in the increase of line intensity of main

strong lines (~ 20% for (110), and 40% for (101) and (301), that is the degree

of crystallinity increased. All these data permit us to estimate that the

content of amorphous phase in mixed films is higher than 50%.

![]() The rutile cell parameters a and c for all three

samples are given below in Table 1. The remarkable decrease of a and c in titania-containing films in comparison with undoped one means that

some type of solid solution has been formed. The decrease of rutile lattice

periods from the values typical for tin oxide my be explained by the lower ion

radius of Ti4+ (0.064 nm) in

comparison to the radius of Sn4+ (0.071 nm)

The rutile cell parameters a and c for all three

samples are given below in Table 1. The remarkable decrease of a and c in titania-containing films in comparison with undoped one means that

some type of solid solution has been formed. The decrease of rutile lattice

periods from the values typical for tin oxide my be explained by the lower ion

radius of Ti4+ (0.064 nm) in

comparison to the radius of Sn4+ (0.071 nm)

![]() Refinement of film morphology and

determination of Sn atoms oxidation state and their local surrounding have been

solved by using of 119Sn MS. The analysis of Mössbauer spectra (the main characteristics of

the MS such as chemical shift (d), quadrupole splitting (E), and relative intensity, A

(area of spectra) are given in Table 1) leads to the following conclusions.

Refinement of film morphology and

determination of Sn atoms oxidation state and their local surrounding have been

solved by using of 119Sn MS. The analysis of Mössbauer spectra (the main characteristics of

the MS such as chemical shift (d), quadrupole splitting (E), and relative intensity, A

(area of spectra) are given in Table 1) leads to the following conclusions.

![]() 1. According to the magnitude of relative

absorption (~60%), the spectrum of the SnO2 film (Fig. 2)

corresponds to a solid sample with a high degree of crystallinity, while the

spectra of the films with x = 10 and

20 can be attributed to solids with a high degree of amorphous SnO2 due

to remarkably lower relative absorption.

1. According to the magnitude of relative

absorption (~60%), the spectrum of the SnO2 film (Fig. 2)

corresponds to a solid sample with a high degree of crystallinity, while the

spectra of the films with x = 10 and

20 can be attributed to solids with a high degree of amorphous SnO2 due

to remarkably lower relative absorption.

|

| Fig.2. Mössbauer spectra of SnO2–TiO2 films. a – SnO2, b – ST10 |

![]() 2. A doublet typical of the Sn atoms

in SnO2 represents the main contribution in all three films (93% –

98%); some increase in the chemical shift, d, in the spectra of mixed films in comparison

to SnO2 film may be associated with a small lengthening of the Sn –

O bonds in amorphous SnO2 due to the change in the s – p bonding.

2. A doublet typical of the Sn atoms

in SnO2 represents the main contribution in all three films (93% –

98%); some increase in the chemical shift, d, in the spectra of mixed films in comparison

to SnO2 film may be associated with a small lengthening of the Sn –

O bonds in amorphous SnO2 due to the change in the s – p bonding.

![]() 3. The distinctly remarkable second

doublet observed for all spectra is attributed to the partly hydrated SnO localized

at the surface. Detailed studies by XPS and inverse photoemission spectra [18, 19] demonstrated

that these "SnO" states are present on the disordered surface of SnO2

or in nanosized SnO2 crystallites. Disorder of SnO2

results in the loss of the symmetry centre of the Sn4+ cation

octahedral surrounding, in splitting of Sn5s and Sn5p atomic orbitals and emerging

of hybrid 5s – 5p orbitals, which are displayed as Sn2+ states. So

"SnO" surface states are indicative of tin atoms in SnO2 disordered

grain boundaries. The non monotonous dependence of Sn2+ content on titania

content will be discussed below.

3. The distinctly remarkable second

doublet observed for all spectra is attributed to the partly hydrated SnO localized

at the surface. Detailed studies by XPS and inverse photoemission spectra [18, 19] demonstrated

that these "SnO" states are present on the disordered surface of SnO2

or in nanosized SnO2 crystallites. Disorder of SnO2

results in the loss of the symmetry centre of the Sn4+ cation

octahedral surrounding, in splitting of Sn5s and Sn5p atomic orbitals and emerging

of hybrid 5s – 5p orbitals, which are displayed as Sn2+ states. So

"SnO" surface states are indicative of tin atoms in SnO2 disordered

grain boundaries. The non monotonous dependence of Sn2+ content on titania

content will be discussed below.

![]() Analysing together the XRD and MS

results one can notice two contradictory phenomena: in spite of the remarkable

change of rutile cell periods in the films studied, only a small increase in

chemical shift (d) with TiO2 content is

observed.

Analysing together the XRD and MS

results one can notice two contradictory phenomena: in spite of the remarkable

change of rutile cell periods in the films studied, only a small increase in

chemical shift (d) with TiO2 content is

observed.

![]() This

contradiction is removed if to take in consideration that the amorphous SnO2

dominates in mixed films while the crystalline rutile phase presents in less

quantity, as evidenced by XRD. In such case the amorphous SnO2 gives

higher contribution into Mössbauer parameters of mixed films

than tin oxide involved into rutile solid solution. The higher degree of

amorphous state in mixed films compared to SnO2 film results in the

small lengthening of the Sn–O bonds. However that effect is not

related to crystalline SnO2 in solid solutions, that is the

influence of titanium oxide on electronic parameters of crystalline SnO2

was not revealed.

This

contradiction is removed if to take in consideration that the amorphous SnO2

dominates in mixed films while the crystalline rutile phase presents in less

quantity, as evidenced by XRD. In such case the amorphous SnO2 gives

higher contribution into Mössbauer parameters of mixed films

than tin oxide involved into rutile solid solution. The higher degree of

amorphous state in mixed films compared to SnO2 film results in the

small lengthening of the Sn–O bonds. However that effect is not

related to crystalline SnO2 in solid solutions, that is the

influence of titanium oxide on electronic parameters of crystalline SnO2

was not revealed.

![]() The electrochemical behavior of the

films under study was similar to previously observed for titania-doped tin

oxide films described in [8, 9]. Galvanostatic charge-discharge curves (first

cycle) of the samples with various titania content demonstrate no pronounced

difference of capacities, whereas the irreversible capacity is noticeably

higher for ST20 sample (Fig. 3). For pure tin oxide (curve 1, Fig. 3) a plateau

at ca. 1 V is observed, which corresponds to reduction with formation of tin

metal; parallel formation of lower valency oxides also can not be excluded at

this potential region [8]. For titania-containing films, similar reduction

process takes place in a wider potential region and does not demonstrate any

special electrochemical features. This behavior can be explained by both

kinetic reasons and more pronounced heterogeneity of doped samples. The role of

dispersion can not be clarified at this stage.

The electrochemical behavior of the

films under study was similar to previously observed for titania-doped tin

oxide films described in [8, 9]. Galvanostatic charge-discharge curves (first

cycle) of the samples with various titania content demonstrate no pronounced

difference of capacities, whereas the irreversible capacity is noticeably

higher for ST20 sample (Fig. 3). For pure tin oxide (curve 1, Fig. 3) a plateau

at ca. 1 V is observed, which corresponds to reduction with formation of tin

metal; parallel formation of lower valency oxides also can not be excluded at

this potential region [8]. For titania-containing films, similar reduction

process takes place in a wider potential region and does not demonstrate any

special electrochemical features. This behavior can be explained by both

kinetic reasons and more pronounced heterogeneity of doped samples. The role of

dispersion can not be clarified at this stage.

|

| Fig.3. Charging curves of tin dioxide films (first cycle) measured in 1M LiN(CF3SO2)2 in dioxolane. 1 – SnO2, 2 – ST10, 3 – ST20. Current density 80 mA g-1. |

![]() Despite of close reversible

capacities observed for the first cycle, the decrease of capacity in the course

of subsequent cycling depends on titania content (Fig. 4). We are concentrated

below on the understanding of micro(nano)structural doping effects which induce

so essential difference of degradation behavior.

Despite of close reversible

capacities observed for the first cycle, the decrease of capacity in the course

of subsequent cycling depends on titania content (Fig. 4). We are concentrated

below on the understanding of micro(nano)structural doping effects which induce

so essential difference of degradation behavior.

|

| Fig.4. Cyclic stability of the reversible capacitance. 1 – SnO2, 2 – ST10, 3 – ST20. Current density 80 mA g-1. |

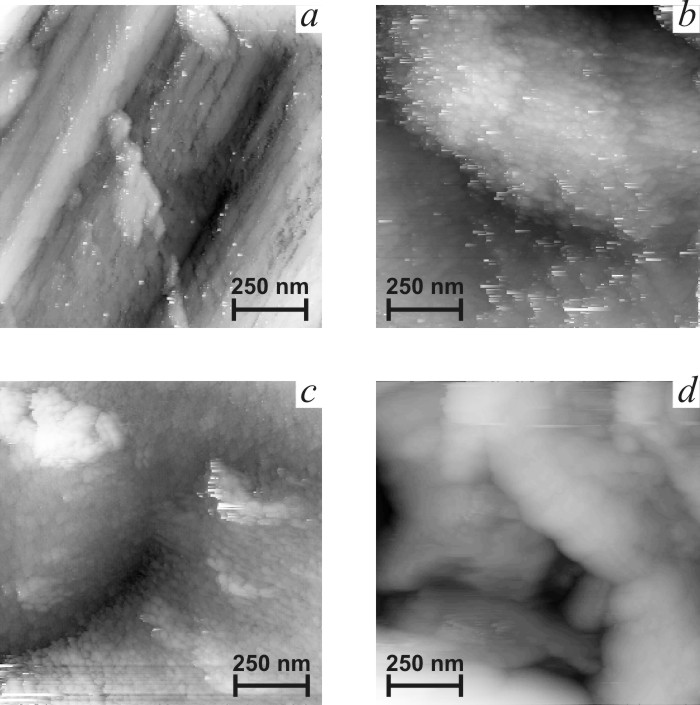

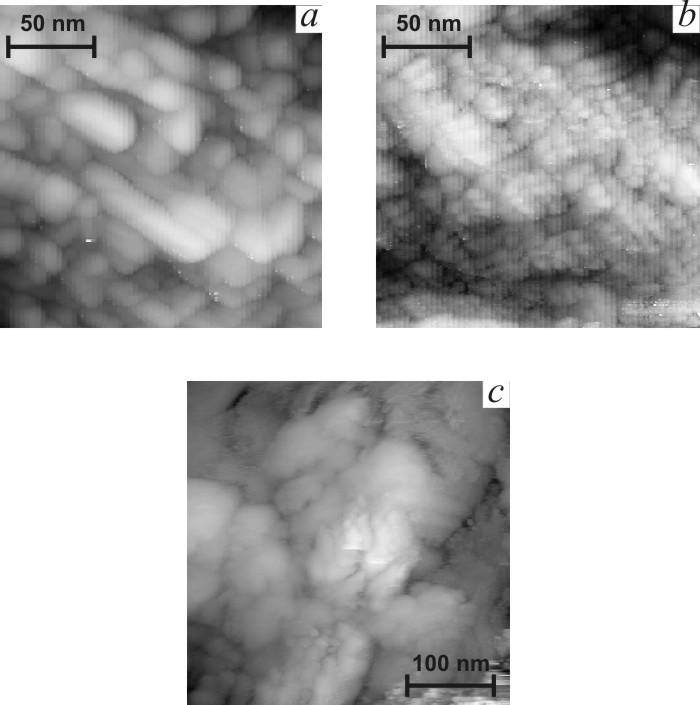

![]() Figs. 5b-d present typical STM

images of the films in mikrometer scale. Image of titanium support in Fig. 5a

is given for comparison. It is easy to observe deep scratches formed in the

course of mechanical polishing. Fast oxidation of titanium surface induced by

the tip is accompanied by formation of loose poorly conducting oxide. Films

under study demonstrate another type of topography, consisting of smooth

globules of 200–700 nm size. Globules consist of smaller nanoparticles, which

size decreases sharply with the increase of titania content (Fig. 6). Crystal

size estimated from STM data for SnO2 film with taking into account

image distortions induced by tip non-ideality [17]) are found to be in

agreement with the sizes estimated from XRD data (Table 1). These data

indicate the higher dispersion of titania-doped films. The clearness of STM images

decreases in the sequence ST0-ST10-ST20, as it can be seen in Fig. 6. Loss of

clearness can result from the increase of the content of amorphous phase.

Figs. 5b-d present typical STM

images of the films in mikrometer scale. Image of titanium support in Fig. 5a

is given for comparison. It is easy to observe deep scratches formed in the

course of mechanical polishing. Fast oxidation of titanium surface induced by

the tip is accompanied by formation of loose poorly conducting oxide. Films

under study demonstrate another type of topography, consisting of smooth

globules of 200–700 nm size. Globules consist of smaller nanoparticles, which

size decreases sharply with the increase of titania content (Fig. 6). Crystal

size estimated from STM data for SnO2 film with taking into account

image distortions induced by tip non-ideality [17]) are found to be in

agreement with the sizes estimated from XRD data (Table 1). These data

indicate the higher dispersion of titania-doped films. The clearness of STM images

decreases in the sequence ST0-ST10-ST20, as it can be seen in Fig. 6. Loss of

clearness can result from the increase of the content of amorphous phase.

|

| Fig.5. Micrometer scale STM images of titanium support (a) and tin oxide films. b – SnO2, c – ST10, d – ST20. |

|

| Fig.6. Nanometer scale STM images of tin oxide films. a – SnO2, b – ST10, c – ST20. |

![]() Tunneling spectra (Fig. 7)

demonstrate the decrease of films conductivity with titania content, and also

more pronounced resistive heterogeneity for higher doping level. Low conductivity

of ST20 films makes it difficult to fix an STM tip and decreases the quality of

STM images of these films. One-two order increase of the resistance of STM gap

at positive currents (i.e. for the highest contributions of film resistance) is

found.

Tunneling spectra (Fig. 7)

demonstrate the decrease of films conductivity with titania content, and also

more pronounced resistive heterogeneity for higher doping level. Low conductivity

of ST20 films makes it difficult to fix an STM tip and decreases the quality of

STM images of these films. One-two order increase of the resistance of STM gap

at positive currents (i.e. for the highest contributions of film resistance) is

found.

|

| Fig.7. Local voltage-current spectra obtained for tin dioxide films. 1 – SnO2, 2 – ST10, 3,4 – ST20. (curves typical for various points of heterogeneous sample). |

![]() Separation of air gap and film

resistance contributions to the total STM gap resistance presents a special

problem. With increase of film resistance, the effect of film on the slope of

voltage-current spectra rises sharply. The reason is as follows: at a certain

fixed base values of bias and current under equilibrium conditions the

resistance of air gap for more resistive films should be much lower, in order

to compensate the increased contribution of the film. Correspondingly, we can

conclude several-order increase of the specific resistance of the films with

titania content. Direct conductivity measurements are complicated by low film

thickness and the existence of more conducting support.

Separation of air gap and film

resistance contributions to the total STM gap resistance presents a special

problem. With increase of film resistance, the effect of film on the slope of

voltage-current spectra rises sharply. The reason is as follows: at a certain

fixed base values of bias and current under equilibrium conditions the

resistance of air gap for more resistive films should be much lower, in order

to compensate the increased contribution of the film. Correspondingly, we can

conclude several-order increase of the specific resistance of the films with

titania content. Direct conductivity measurements are complicated by low film

thickness and the existence of more conducting support.

![]() Qualitatively, the observed

resistance vs. composition dependence agrees well with previous data of direct

conductivity measurements of similar films on insulating supports [2].

Qualitatively, the observed

resistance vs. composition dependence agrees well with previous data of direct

conductivity measurements of similar films on insulating supports [2].

![]() Increased heterogeneity of local

conductivity observed for the films with higher titania content can be referred

to more pronounced heterogeneity of chemical/phase composition. For ST20,

heterogeneity results in one order difference of the slopes of voltage-current

spectra measured in various points (curves 3 and 4 in Fig. 7). For less doped

films, difference in local conductivity of various areas is clearly seen in

more sensitive voltage-distance spectra (Fig. 8). For certain points these

spectra are smooth, with the changes of distance below 5 nm (curve 1 in Fig. 8).

Curves of this type correspond to more conductive areas. The spectra of similar

shape with close distance values were obtained also for pure tin dioxide. For

some other areas (which topographic images usually look more cloudy)

voltage-distance spectra are asymmetric and include stepwise features with

distance changes of 50 – 100 nm (curve 3 in Fig. 8). We associate this sharp distance

increase with the fact that at low voltages the film conductivity is too low

for passing the established current. Under constant current mode this situation

results in closer approaching of tip and appearance of direct tip-sample

contact, with partial penetration of tip into the film. In the framework of

this hypothesis the appearance of stepwise features manifests much higher local

resistance of the areas under study.

Increased heterogeneity of local

conductivity observed for the films with higher titania content can be referred

to more pronounced heterogeneity of chemical/phase composition. For ST20,

heterogeneity results in one order difference of the slopes of voltage-current

spectra measured in various points (curves 3 and 4 in Fig. 7). For less doped

films, difference in local conductivity of various areas is clearly seen in

more sensitive voltage-distance spectra (Fig. 8). For certain points these

spectra are smooth, with the changes of distance below 5 nm (curve 1 in Fig. 8).

Curves of this type correspond to more conductive areas. The spectra of similar

shape with close distance values were obtained also for pure tin dioxide. For

some other areas (which topographic images usually look more cloudy)

voltage-distance spectra are asymmetric and include stepwise features with

distance changes of 50 – 100 nm (curve 3 in Fig. 8). We associate this sharp distance

increase with the fact that at low voltages the film conductivity is too low

for passing the established current. Under constant current mode this situation

results in closer approaching of tip and appearance of direct tip-sample

contact, with partial penetration of tip into the film. In the framework of

this hypothesis the appearance of stepwise features manifests much higher local

resistance of the areas under study.

|

| Fig.8. Local voltage-distance spectra of ST10 sample: representative types of curves observed at various points of the sample. |

![]() There are a lot of surface areas for

which an intermediate type of voltage-distance spectral behavior is observed

(curve 2 In Fig. 8), and correspondingly intermediate values of conductivity

can be concluded for these areas.

There are a lot of surface areas for

which an intermediate type of voltage-distance spectral behavior is observed

(curve 2 In Fig. 8), and correspondingly intermediate values of conductivity

can be concluded for these areas.

![]() For ST20 samples, the stepwise

behavior of voltage-distance spectra is observed for any point of the surface.

Typical distances appear to be up to 1 mm, which value exceeds the vertical resolution

of the STM device. This observation obtained with the most resistive samples confirms

the interpretation of voltage-distance anomalous behavior discussed above.

For ST20 samples, the stepwise

behavior of voltage-distance spectra is observed for any point of the surface.

Typical distances appear to be up to 1 mm, which value exceeds the vertical resolution

of the STM device. This observation obtained with the most resistive samples confirms

the interpretation of voltage-distance anomalous behavior discussed above.

![]() The pronounced increase of the total

film resistance can result from the changes in conductivity of the crystalline

solid solution SnO2-TiO2, and also from the increase of

contribution of the poorly conducting amorphous component (both effects are

assumed to be size-dependent). The specific features of fixing the tip in the

gap can be the reason of the change of image nature: the increase of total

resistance can lead from the imaging of conductive crystalline component to the

imaging of amorphous component and (or) simultaneous imaging of both components.

The appearance of steps in the voltage-distance spectra agrees with the

assumption about the abovementioned change. The qualitative difference of ST20

STM images as compared to less doped films also supports this assumption.

However we can not determine the quantity of amorphous component from STM data.

The pronounced increase of the total

film resistance can result from the changes in conductivity of the crystalline

solid solution SnO2-TiO2, and also from the increase of

contribution of the poorly conducting amorphous component (both effects are

assumed to be size-dependent). The specific features of fixing the tip in the

gap can be the reason of the change of image nature: the increase of total

resistance can lead from the imaging of conductive crystalline component to the

imaging of amorphous component and (or) simultaneous imaging of both components.

The appearance of steps in the voltage-distance spectra agrees with the

assumption about the abovementioned change. The qualitative difference of ST20

STM images as compared to less doped films also supports this assumption.

However we can not determine the quantity of amorphous component from STM data.

![]() Based on STM,

XRD and MS results we could propose the following model of nanostructured doped

films.

Based on STM,

XRD and MS results we could propose the following model of nanostructured doped

films.

![]() The highly dispersed

(on STM base) rutile phase observed in mixed films studied in the present work

may be classified as a solid solution with short range order or as a

nanocomposite containing both SnO2 and TiO2 nanoclusters

(<1 nm in size). Poorly ordered tin and titanium oxide nanoclusters are

randomly distributed in partially hydrated amorphous tin oxide matrix. The

latter are pierced by ultra fine pores which contain H2O molecules

and Cl- ions. The crystalline SnCl2 intercalation phase

has been found to be the precursor of that nanostuctured forms [2, 11]. The

quantities of that rutile phase in both mixed films are approximately equal, as

limited by the content of Sn(II) anionic chloro complexes in origin solution of

tin and titanium chlorides. The concentration of these complexes is constant because

of constant cHCl.

The highly dispersed

(on STM base) rutile phase observed in mixed films studied in the present work

may be classified as a solid solution with short range order or as a

nanocomposite containing both SnO2 and TiO2 nanoclusters

(<1 nm in size). Poorly ordered tin and titanium oxide nanoclusters are

randomly distributed in partially hydrated amorphous tin oxide matrix. The

latter are pierced by ultra fine pores which contain H2O molecules

and Cl- ions. The crystalline SnCl2 intercalation phase

has been found to be the precursor of that nanostuctured forms [2, 11]. The

quantities of that rutile phase in both mixed films are approximately equal, as

limited by the content of Sn(II) anionic chloro complexes in origin solution of

tin and titanium chlorides. The concentration of these complexes is constant because

of constant cHCl.

![]() As concerned

to the amorphous phase, tunneling spectroscopy evidences the remarkable

increase of the resistance with TiO2 content. For ST20 electrode

such increase occurs for any point of the surface (both for globules with

crystalline core and completely

amorphous globules). The high resistance is typical for the surface of the

nanoparticles composing of tin–titanium oxide solid solution [1, 2]. The high

resistance of completely amorphous globules means that amorphous SnO2

phase of the electrodes is also essentially enriched with TiO2.

As concerned

to the amorphous phase, tunneling spectroscopy evidences the remarkable

increase of the resistance with TiO2 content. For ST20 electrode

such increase occurs for any point of the surface (both for globules with

crystalline core and completely

amorphous globules). The high resistance is typical for the surface of the

nanoparticles composing of tin–titanium oxide solid solution [1, 2]. The high

resistance of completely amorphous globules means that amorphous SnO2

phase of the electrodes is also essentially enriched with TiO2.

![]() The

remarkable increase of the amorphous mixed phase may result from the higher

number of Ti (IV)

hydroxooxo complexes

and higher degree of their polymerisation in initial solution with

concentration of TiCl4

of 1 mol/l. These polymeric species, which in essence appear the nuclea of

hydrated titanium oxide, favor the hydrolysis of SnCl2. The latter

process induces the formation of mixed hydrated tin and titanium oxides, which

remain in amorphous state up to 450 oC.

The

remarkable increase of the amorphous mixed phase may result from the higher

number of Ti (IV)

hydroxooxo complexes

and higher degree of their polymerisation in initial solution with

concentration of TiCl4

of 1 mol/l. These polymeric species, which in essence appear the nuclea of

hydrated titanium oxide, favor the hydrolysis of SnCl2. The latter

process induces the formation of mixed hydrated tin and titanium oxides, which

remain in amorphous state up to 450 oC.

![]() In

conclusion, the existance of two types of precursors of the main components in

mixed films was the reason of the different content of Sn2+ as observed my MS. The increase

of SnO in the ST10 film in comparison to SnO2 film may be explained

by both the dispersion of nanoparticles observed by STM and by the role of

precursor of the rutile solid solution (crystalline SnCl2

intercalation phase). In the course of decomposition of the latter the

amorphous SnO2 layers containing up to 15% SnO cover the globule

surface [2]. The increase of Ti component results in the higher content of

tin(IV) and titanium hydrated forms [11]. Therefore we can atribute the

decrease of SnO content in the film x=20

with the latter effect.

In

conclusion, the existance of two types of precursors of the main components in

mixed films was the reason of the different content of Sn2+ as observed my MS. The increase

of SnO in the ST10 film in comparison to SnO2 film may be explained

by both the dispersion of nanoparticles observed by STM and by the role of

precursor of the rutile solid solution (crystalline SnCl2

intercalation phase). In the course of decomposition of the latter the

amorphous SnO2 layers containing up to 15% SnO cover the globule

surface [2]. The increase of Ti component results in the higher content of

tin(IV) and titanium hydrated forms [11]. Therefore we can atribute the

decrease of SnO content in the film x=20

with the latter effect.

![]() Doping of SnO2

with TiO2 results in pronounced dispersion of the solid. This effect

is induced by 2-2.5 times decrease of nanoparticles forming the films, and also

by oxide dispersion in the shorter scale. Nanoparticles consist of disordered

nanostructured solid solutions (presented by SnO2 and TiO2

nanoclusters of nanometer-scale size) and amorphous phase formed by both SnO2

and TiO2. The portion of amorphous phase in the films under study is

essentially higher than in electrode materials studied in our previous works

[1, 2], and its reason is the change of hydrolysis conditions for initial

solutions of salt reagents. Just this extremely high dispersity of titana,

which is a component stable to reduction with lithium, can be considered as a

reason of better degradation stability with simultaneous keeping high capacity

values (typical for nanostructured tin oxides). Direct observation of the

increase of tin dioxide dispersion with doping titania content is obtained.

Doping of SnO2

with TiO2 results in pronounced dispersion of the solid. This effect

is induced by 2-2.5 times decrease of nanoparticles forming the films, and also

by oxide dispersion in the shorter scale. Nanoparticles consist of disordered

nanostructured solid solutions (presented by SnO2 and TiO2

nanoclusters of nanometer-scale size) and amorphous phase formed by both SnO2

and TiO2. The portion of amorphous phase in the films under study is

essentially higher than in electrode materials studied in our previous works

[1, 2], and its reason is the change of hydrolysis conditions for initial

solutions of salt reagents. Just this extremely high dispersity of titana,

which is a component stable to reduction with lithium, can be considered as a

reason of better degradation stability with simultaneous keeping high capacity

values (typical for nanostructured tin oxides). Direct observation of the

increase of tin dioxide dispersion with doping titania content is obtained.

![]() Nanoheterogeneous character of

rutile phase observed for the films under study is confirmed by XRD and

Mössbauer spectroscopy investigations.

Nanoheterogeneous character of

rutile phase observed for the films under study is confirmed by XRD and

Mössbauer spectroscopy investigations.

![]() The decrease of particle size is

assumed to be a reason of more slow degradation in the course of cycling in

lithium-containing solutions (Fig. 3). Actually, the enlargement of metallic

tin particles should be very slow when these particles are separated by low

conductive (and most probably amorphous) oxide with high titania content.

Heterogeneity of doped films confirmed by local tunneling spectroscopy can be

considered as a possible reason of the absence of plateau. Both heterogeneity

of ohmic drop and equilibrium potentials for certain redox transformations of

chemically different areas can be assumed, and these two effects can hardly be

separated at this stage.

The decrease of particle size is

assumed to be a reason of more slow degradation in the course of cycling in

lithium-containing solutions (Fig. 3). Actually, the enlargement of metallic

tin particles should be very slow when these particles are separated by low

conductive (and most probably amorphous) oxide with high titania content.

Heterogeneity of doped films confirmed by local tunneling spectroscopy can be

considered as a possible reason of the absence of plateau. Both heterogeneity

of ohmic drop and equilibrium potentials for certain redox transformations of

chemically different areas can be assumed, and these two effects can hardly be

separated at this stage.

![]() Interpretation of electrochemical

data for highly resistive films is complicated by the uncertainty of potential

values, which are distorted by the ohmic drop and possible heterogeneity of

potential distribution along the surface. Under these circumstances one can not

exclude the selective solvent discharge at already formed metallic fragments,

which gives additional contribution to the total charge.

Interpretation of electrochemical

data for highly resistive films is complicated by the uncertainty of potential

values, which are distorted by the ohmic drop and possible heterogeneity of

potential distribution along the surface. Under these circumstances one can not

exclude the selective solvent discharge at already formed metallic fragments,

which gives additional contribution to the total charge.

![]() The authors are grateful to

A.V.Denisov for technical support of STM and spectroscopic studies. The study

is supported by RFBR, projects 03-03-32422-a, 02-03-32226-a.

The authors are grateful to

A.V.Denisov for technical support of STM and spectroscopic studies. The study

is supported by RFBR, projects 03-03-32422-a, 02-03-32226-a.

Table 1. XRD and Mössbauer spectra data for SnO2 – TiO2 films.

| Electrodes STx | Rutile cell periods, nm | Dav, nm* | Mössbauer spectra data | |||

| Tin oxide doublet | d, mm/s vs. CaSnO3 | DE,mm/s | A,% | |||

| SnO2(x = 0) | a= 0.4734 c= 0.3175 |

11.0 ± 1.0 | SnO2 | –0.0076±0.0016 | 0.532±0.004 | 98.34 |

| SnO | 2.83±0.12 | 1.91±0.12 | 1.72 | |||

| ST10 (x = 10%) | a= 0.4705 c= 0.3165 |

SnO2 | 0.0122±0.0038 | 0.511±0.010 | 93.45 | |

| SnO | 2.951±0.072 | 1.82±0.13 | 6.55 | |||

| ST20 (x = 20%) | a= 0.4670 c= 0.3118 |

SnO2 | 0.0176±0.0043 | 0.516±0.012 | 98.05 | |

| SnO | 2.85±0.12 | 2.08±0.24 | 1.95 | |||

* Dav — the average size of crystallites determined

with the use of FWHM for (110) reflection by Sherrer method. (![]() ,

, ![]() nm [16])

nm [16])